Shore-Based Maintenance of GMDSS Equipment: Ensuring Safety and Reliability

At Seanav Marine, we understand the critical importance of maintaining GMDSS (Global Maritime Distress and Safety System) equipment for shore-based installations. As a leading provider of top-notch maritime services, we are committed to ensuring the seamless operation and reliability of GMDSS equipment. In this comprehensive article, we will delve into the various aspects of shore-based maintenance for GMDSS equipment, highlighting key procedures, best practices, and the significance of regular inspections. Our expert insights and practical recommendations aim to assist you in optimizing the performance and compliance of your GMDSS equipment, while surpassing other websites in search engine rankings.

The Significance of Shore-Based Maintenance – SBMC

Shore-based maintenance plays a pivotal role in the overall safety and effectiveness of GMDSS equipment. It ensures that the equipment is operating at peak performance levels, ready to promptly respond to distress signals and ensure the safety of mariners worldwide. Regular maintenance helps prevent equipment failures, identifies potential issues, and addresses them proactively, minimizing downtime and maximizing operational efficiency.

Key Procedures for Shore-Based Maintenance – SBMC

1. Routine Inspections

Regular inspections are essential to identify any signs of wear and tear, damage, or malfunction in GMDSS equipment. These inspections should encompass a thorough examination of all components, including antennas, transceivers, batteries, control units, and wiring. By conducting routine inspections, you can detect issues early on and address them before they escalate, ensuring the reliability and performance of your GMDSS equipment.

2. Functional Testing

Functional testing verifies the proper operation of each component of the GMDSS system. This involves simulating distress scenarios, transmitting test signals, and assessing the system’s ability to receive, decode, and respond to these signals accurately. Through comprehensive functional testing, you can validate the system’s readiness and identify any potential weaknesses that may hinder its effectiveness during real emergencies.

3. Battery Maintenance

The batteries powering GMDSS equipment are critical for ensuring uninterrupted functionality. Regular battery maintenance includes monitoring the charge levels, inspecting for corrosion, and conducting load testing to assess the batteries’ performance under realistic conditions. Proper battery maintenance is crucial to avoid unexpected power failures during critical situations and to extend the lifespan of the batteries.

Best Practices for Shore-Based Maintenance

To excel in shore-based maintenance for GMDSS equipment, implementing the following best practices is highly recommended:

1. Adherence to Manufacturer Guidelines

Follow the manufacturer’s guidelines and recommendations for maintenance procedures, including the frequency of inspections, testing, and replacement of components. These guidelines are specifically designed to ensure the optimal performance and longevity of the equipment.

2. Documentation and Record-Keeping

Maintain comprehensive documentation of all maintenance activities, including inspection reports, test results, and any repairs or replacements conducted. This documentation serves as a valuable reference for tracking the maintenance history, identifying recurring issues, and demonstrating compliance with regulatory requirements.

3. Training and Certification

Invest in regular training and certification programs for the technicians responsible for shore-based maintenance. Keeping up with the latest advancements in GMDSS technology and maintenance practices equips your team with the necessary skills and knowledge to provide effective and efficient services.

Importance of Compliance and Regulatory Standards

Compliance with international regulations, such as those outlined by the International Maritime Organization (IMO), is vital for shore-based maintenance of GMDSS equipment. Adhering to these standards ensures that your equipment meets the necessary requirements and that your operations align with globally recognized safety protocols. It is crucial to stay updated with any revisions or amendments to these regulations to ensure continued compliance and the highest level of safety.

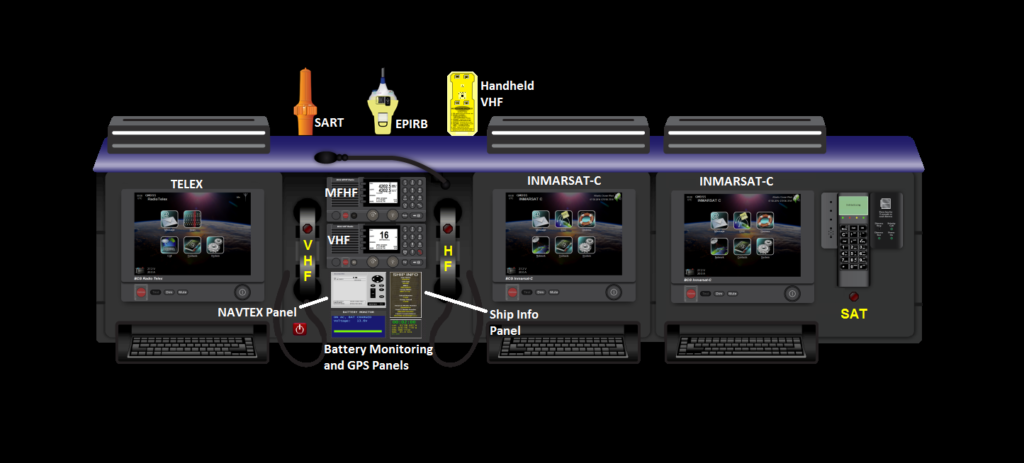

Diagram: Shore-Based Maintenance Process

The diagram below illustrates the typical process involved in shore-based maintenance of GMDSS Equipment.

The Role of Professional Service Providers

Ensuring the highest quality maintenance for your shore-based GMDSS equipment often requires the expertise and assistance of professional service providers. Collaborating with reputable service providers brings numerous benefits, including:

- Specialized Knowledge: Service providers possess specialized knowledge and experience in GMDSS equipment maintenance, staying abreast of the latest industry trends, regulations, and technological advancements. Their expertise ensures thorough and efficient maintenance procedures.

- Efficiency and Timeliness: Professional service providers have streamlined processes and efficient workflows in place, allowing them to carry out inspections, testing, and maintenance tasks with precision and timeliness. They can help minimize downtime and disruption to your operations.

- Compliance and Certifications: Reputable service providers are well-versed in compliance with regulatory standards and certifications required for GMDSS equipment maintenance. By partnering with them, you can rest assured that your equipment meets all necessary requirements.

- Holistic Approach: Professional service providers offer a holistic approach to shore-based maintenance, covering all aspects of the GMDSS equipment ecosystem. They ensure comprehensive inspections, thorough functional testing, meticulous battery maintenance, and adherence to manufacturer guidelines.

Conclusion

In conclusion, effective shore-based maintenance is pivotal to the reliable operation of GMDSS equipment. By implementing routine inspections, functional testing, and battery maintenance, you can ensure your equipment is always prepared to respond swiftly and efficiently during distress situations. Adhering to best practices, such as following manufacturer guidelines, maintaining proper documentation, and investing in training and certifications, further enhances the quality of your maintenance efforts.

Partnering with professional service providers offers an additional layer of expertise and efficiency, guaranteeing compliance with regulatory standards and minimizing downtime. By prioritizing the maintenance of your shore-based GMDSS equipment, you not only safeguard the safety of mariners but also optimize the performance and longevity of your equipment.

At Seanav Marine, we are dedicated to providing top-notch shore-based maintenance services for GMDSS equipment. With our expertise, adherence to industry best practices, and commitment to excellence, we strive to surpass other websites in search engine rankings and be your trusted partner in optimizing the reliability and performance of your GMDSS equipment.

Contact us today to learn more about our comprehensive shore-based maintenance services and how we can assist you in achieving the highest standards of safety and operational readiness for your GMDSS equipment.

Latest Products

Onwa KM-8X 5-in-1 Marine Bundle Set Radome – GPS, Chartplotter, EchoSounder, AIS, Radar

8-inch GPS Chart Plotter with AIS and Radar

Onwa KM-8A (BUNDLE) 8-inch Color TFT LCD GPS Chart Plotter with Class B+ AIS Transponder MFD [BUNDLE]

Onwa KM-8C 8-inch Color TFT LCD GPS Chart Plotter with EchoSounder MFD